Trading circles are rife with all sorts of different payment terms. Both buyers and sellers are trying their best to secure their cash and ensure the products they receive are as per the standard expected. There are many horror stories one will hear across the UAE wholesale market. Stores that result in hundreds of thousands of dirhams in losses. As a result, many traders are moving towards the consignment inventory model in the UAE with their overseas partners to ensure that supplier takes their responsibility seriously.

This is an underutilized way of creating a win-win partnership between suppliers and sales (traders/retailers) as long as both are willing to share the risks and rewards.

Also important to consider the VAT implications

To help illustrate this further I have detailed the concept and highlighted some of the Pros and Cons

Consignment inventory?

This is an agreement between the consignor (supplier/wholesaler) who agreed to provide the goods to the consignee (trader/ retailer) with the consignee paying upfront for the goods. The consignee can suggest the goods based on the market feedback/trends but ultimately the consignor makes the decision. The consignor has the choice of product to deliver and retains ownership of it. Pricing for the goods is only established once the goods have been sold and the consignee pays for the goods sold.

For example, a fruit trader in Sri Lanka might want to break into the lucrative UAE fresh product market, but their quality is relatively unknown and they could have a hard time selling the goods and getting payment.

If the vendor offers the goods on consignment to a reputed local firm. The vendor will then stock the products in their stores and pay for what has been sold.

This arrangement is hugely beneficial for both parties but also carries some risks

Below are some of the Pros and Cons

Pros and Cons of consignment inventory for vendors

Pros

- Enter new markets at allow cost

In the above fresh produce example, providing the goods on consignment allows the vendor to enter a new market at a fraction of the costs involved in the setup.

- Low inventory carrying costs

Inventory is expensive and in the case of fresh produce a ticking time bomb. By shipping, a portion of the inventory to the trader vendors can lower their carrying costs

- Quicker inventory turnover

Adding a commission can ensure a faster turnaround time as the trader will only realize his commission once the goods have been sold out

- Maximize the return

Converting the sale to a commission-only model will ensure that the trader will push the product out at the maximum price possible as they would get a large commission-based n a higher price.

Cons

- Cash-flow impact

Suppliers won’t get paid till some or all the goods are sold out by the trader. Goods that aren’t sold can’t be returned to the vendor (unless specially agreed). This has an impact on the cash flow and makes it volatile as there is no visibility of how much of the goods will be sold

- Payment Security

The main risk in this model is not getting paid. There are many unscrupulous trades/ retailers in the UAE who do an about-face once the payment is due. Signatories go on holidays, accountants are unable to find the documents, and Bank holidays – so many reasons for such little time. I cannot stress enough that you need to ensure that you only work with reputed suppliers e.g. Grocer Global FZE for fresh produce

Pros and Cons of consignment inventory for Traders/ Retailers

Pros

- Reduced ownership costs

Traders/ retailers can sell the inventory without the pains associated with owning it. This lowers the cost of ownership and holding costs

- Reduced Risks

Not paying for the goods upfront frees up cash to invest in resources or make purchases of other critical items required to run or improve the audience or sales performance of the goods

- Improved Cash-flow

The trader/ retailer pays for the goods once they are sold. The goods are still owned by the vendor and they are still responsible for them. This frees the trader/ retailer to stock more inventory at lower costs to reduce the chances of stockouts or dead inventory

Cons

- Damage inventory

The holding period for inventory is directly proportional to the increased chances of inventory getting damaged. This is more so in the case of fresh produce having a limited shelf life.

In our operations at Grocer Global FZE, this is one of the biggest challenges that we face luckily check has been put in place to mitigate the risk as much as possible. Sometimes suppliers refuse to accept the damages and this usually means that the trader/ retailer is obligated to buy it.

- Pilferage

The second biggest issue faced by most traders/ retailers is a mismatch in stock counts. Although goods are the responsibility of the vendor they should still be treated just like regular stocks and tracked to ensure reduced pilferage, goods must follow the inventory management system for tracking goods in and out and in transit.

In our operations at Grocer Global FZE as all fresh produce is stored in reefer containers until it is sold. This means that containers are opened many times a day for deliveries and goods get lost during transit. Checks must be put in place from the loading to the delivery point to reduce this, unfortunately, there are many instances where this can happen and so it can only be reduced and not eliminated. Always make a provision as we have for pilferage @ 5% or more.

How to make this mutually beneficial

- Sign a clear contract – Clearly outline the responsibilities and expectations of both parties in a document, this should include who is responsible for damages and how they will be handled, and how long the inventory can be held. how stocks will be disposed of or returned, etc. Ensure that is as detailed as possible and leave nothing to interpretation. Clarify all points before you move forward. These documents are critical at the time of disputes or disagreements

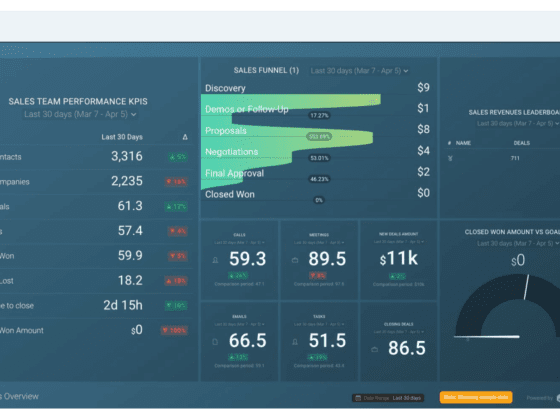

- Shared Inventory status – Invest in a platform that can provide real-time inventory status to both parties as required. Transparency is key to a lasting business relationship. If you do not have the funds for full-fledged software set it up in Microsoft Excel by using a template. Share the file on google drive or Dropbox or another cloud platform. This will also help the vendor prepare the next shipment as they hit the minimum order levels

- Mutual Trust develops into Mutually beneficial relationships – Honest on both sides is critical to developing a long-lasting relationship. The process listed above is one perspective and can be tinkered with and changed completely depending on the situation and agreements. Both partners need to provide insight and assistance as required to ensure the fastest inventory turnover rate.